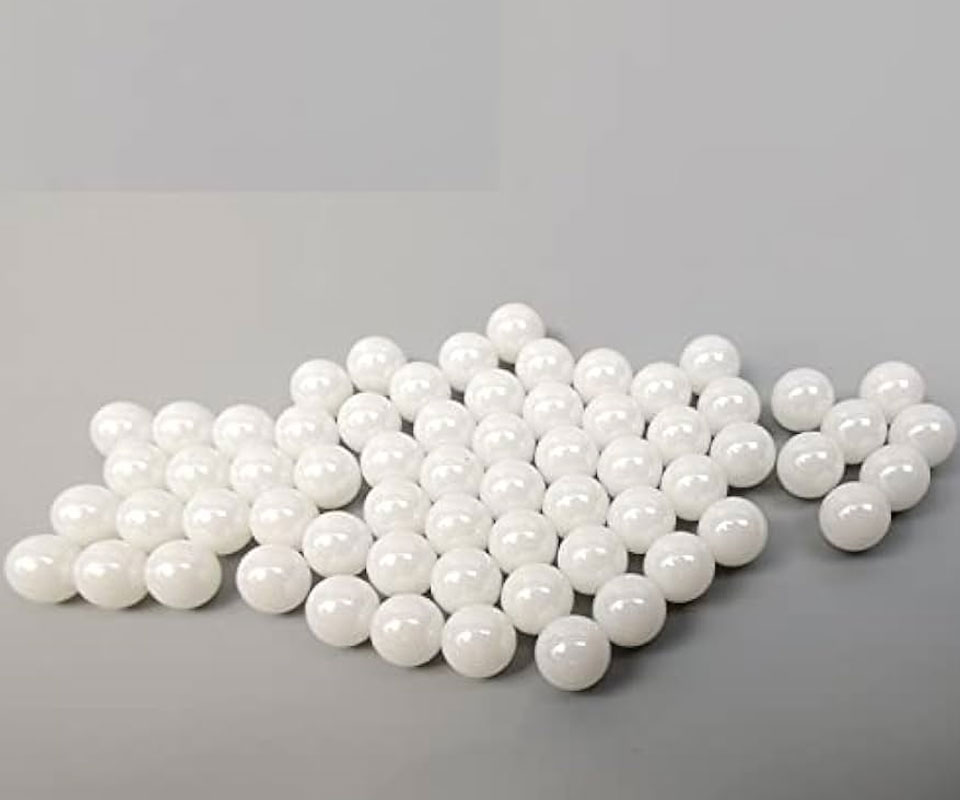

Zirconium Oxide (ZrO2)

Zirconium oxide (ZrO2), commonly referred to as zirconia, distinguishes itself from other ceramic materials due to its exceptional resistance to crack propagation. This characteristic, combined with its high thermal expansion, makes zirconium oxide ceramics particularly suitable for applications that require the joining of ceramic and steel components.

Zirconium oxide is a white crystalline oxide derived from zirconium, with its most naturally occurring form being the mineral baddeleyite, which features a monoclinic crystalline structure. Products made from zirconium oxide are known for their outstanding mechanical properties and stability under high-temperature conditions.

As an advanced ceramic material, zirconia is predominantly utilized in the manufacturing of various hard ceramics, with a significant application in dental implants. Its hardness, chemical inertness, and biocompatibility contribute to its widespread use in this field. Nevertheless, the applications of zirconia extend beyond dentistry, owing to its diverse range of beneficial properties.

Physical properties :

- High thermal expansion (α=11 x 10-6/K, similar to some types of steel)

- Excellent thermal insulation/low thermal conductivity (2.5 to 3 W/mK)

- Very high resistance to crack propagation, high fracture toughness (6.5 to 8 MPam

- Excellent thermal resistance and mechanical properties at elevated temperatures.

- It is very strong and hard, has superior wear resistance, stability, and is resistant to scratching.

- Absence of innate brittleness of some other types of technical ceramics

- Very high room-temperature strength

- Very high fracture toughness

- High hardness and density

- Good frictional behavior

- Low thermal conductivity

- Solid electrical insulation